Micropake® x-ray detectable yarn

Strong and flexible

Micropake®

Phthalate free

Unlike many other alternatives our x-ray detectable thread is phthalate free.

Full R&D Support

SFM has 40+ years of experience in manufacturing x-ray detectable yarn in the UK. It is melt-spun and wound on site. Many variations have been developed for our customers over the years.

Applications

Medical Gauzes

Surgical sponges

Veterinary applications

Cutting guides

Catheters

Processing

Weaving

Stitching

Heat bonding

Product Specifications

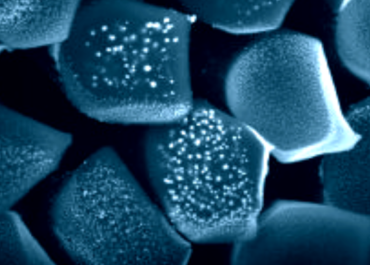

Micropake® is a phthalate-free X-ray detectable yarn melt-spun from polypropylene with a high loading of barium sulphate (60%). It is often used in the manufacture of x-ray detectable gauze swabs and sponges, although in recent years our Micropake® has seen uses in very different sectors and applications. Available in various decitex and colours.

SFM European Manufacturer of Phthalate-Free X-Ray Detectable Yarn with 60% Barium Sulphate

Micropake® is a phthalate-free X-ray detectable yarn based on polypropylene used in the manufacture of X-ray detectable gauze swabs and sponges.

The thread is typically made up of 40 filaments wrapped with a fine polyester thread and can be manufactured in a range of linear densities to suit customer specifications. This provides a key advantage in that the multi-filament thread is soft and flexible in nature, which when coupled with good tensile strength, allows Micropake® to be woven. The yarn may also be thermally or ultrasonically bonded to fabrics.

Micropake® is available in three different specifications that meet the x-ray opacity requirements of the British Pharmacopeia.

All our products are manufactured in the UK, from class 8 clean room facilities located in Coventry. Our alginates, reinforced alginates, gelling fibre products are all manufactured from raw materials that are sustainable and using a manufacturing process which minimises waste as far as possible.

MP600

MP600 is SFM’s thicker x-ray detectable yarn with a minimum barium sulphate content of 60%, a decitex of 3420-4180 and a minimum tenacity of 1.9 cN/tex.

MOQ: Usually ~103kg

MP632

With a minimum barium sulphate content of 60%, the MP632 product has a has a decitex of 3100-3400 and a minimum tenacity of 2.1 cN/tex.

MOQ: Usually ~103kg

MP Black 06

Similar to MP 632, Micropake Black 06 has a minimum barium sulphate content of 60%decitex of 3100-3400 and a minimum tenacity of 2.1 cN/tex.

MOQ: Usually ~103kg

We keep some stock for the most commonly requested sizes for our x-ray detectable yarns, and therefore can deliver these on-demand. Most of our products are made to order, and whilst we often will work 12 weeks ahead with most of our customers to help manage a smooth continuity of supply which is particularly relevant with the current Covid-19 pandemic; We can often deliver in a few weeks and will try our best to meet your schedule. Packed and sterile products however will be between 8 to 12 weeks once the packaging has been fully approved.

SFM implements and complies with the ISO 13485 (EU, Canada, RoW), 21 CFR 820 (USA) and Ordinance 169 (Japan). We are experts in the overall planning and delivery of regulatory compliance throughout a product’s life cycle. We deliver products CE marked and or FDA cleared. Our Regulatory Affairs and Quality team manage our Integrated QMS.