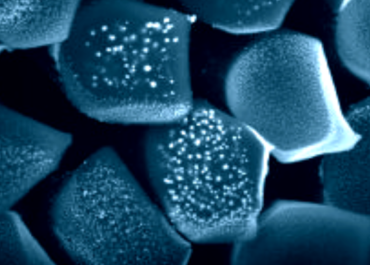

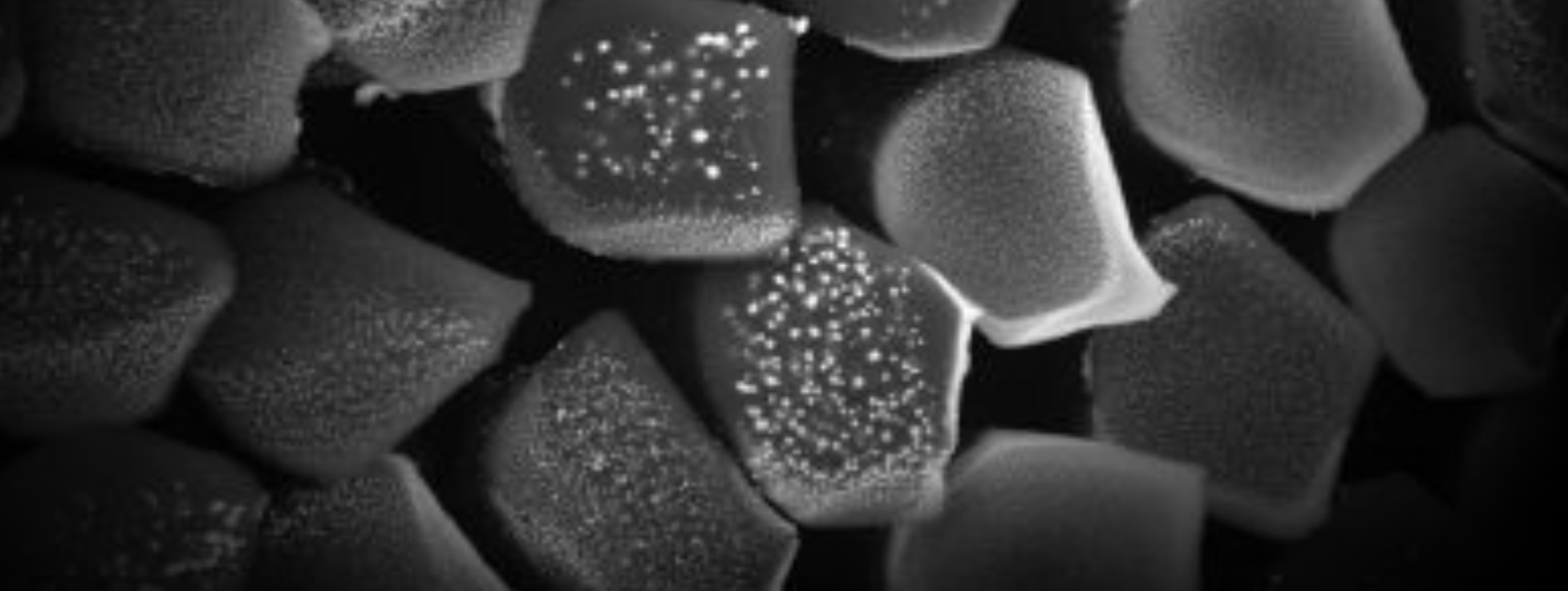

Antibacterial Nanotech CMC

Antibacterial, Highly Absorbent with

enhanced wet strength

Sustainable

Fibres and fabrics directly derived from abundant and naturally occurring resources

Biocompatibility

Unique de-watering process which enhances the fibre strength, reduces fibre shed and provides increased biocompatibility.

Absorbency

Wet Strength

Optimised needle bonding process designed to balance the conflicting requirements of strength and absorbency

Product specifications

This is our latest product to join the Carboxymethyl cellulose (CMC) family. A proprietary blend of three fibers, which encapsulates SFM’s novel silver nanotechnology developed for its low cytotoxicity profile with consistent antibacterial and antimicrobial efficacy. In markets requiring a CE mark, the product is supplied as cut pieces, packaged and sterile. Our latest novel silver CMC is offered as 120gsm, 160gsm, and 200gsm. Our silver CMC is CE marked. Please check our modified cellulose options for non-silver versions.

Looking for more details? Click here to contact us

- Close entanglement of fibre for enhanced wet tensile strength .

- High vertical absorption of exudate, protects wound edge and surrounding skin from maceration.

- Maintains a moist healing environment.

- High dressing strength and integrity (1).

- Retains bacteria in the dressing.

- Sustained antibacterial and antimicrobial activity(2).

- Conformable dressing.

- Supports autolytic debridement.

- various GSM and cut sizes available on request

- Biodegradable material

- Effective against: Gram positive and gram negative bacteria

- Moderately to heavily exuding superficial or deep wounds

- Acute or chronic wounds (leg ulcers, pressure ulcers (Stage II to IV) and diabetic ulcers)

- Surgical wounds (e.g post-operative, wounds left to heal by secondary intent and donor sites)

- Traumatic wounds (e.g abrasions and lacerations)

- Wounds that are prone to bleeding (e.g mechanically or surgically debrided and donor sites)

- Partial thickness burns

All our products are manufactured in the UK, from class 8 clean room facilities located in Coventry. Our alginates, reinforced alginates, gelling fibre products are all manufactured from raw materials that are sustainable and using a manufacturing process which minimises waste as far as possible.

We can currently provide our products in several sizes from 5cm x 5cm cut pieces to 20cm x 30cm, although we can provide larger sizes on demand.

We keep some stock for the most commonly requested sizes for our x-ray detectable yarns, and therefore can deliver these on-demand. Most of our products are made to order, and whilst we often will work 12 weeks ahead with most of our customers to help manage a smooth continuity of supply which is particularly relevant with the current Covid-19 pandemic; We can often deliver in a few weeks and will try our best to meet your schedule. Packed and sterile products however will be between 8 to 12 weeks once the packaging has been fully approved.

SFM implements and complies with the ISO 13485 (EU, Canada, RoW), 21 CFR 820 (USA) and Ordinance 169 (Japan). We are experts in the overall planning and delivery of regulatory compliance throughout a product’s life cycle. We deliver products CE marked and or FDA cleared. Our Regulatory Affairs and Quality team manage our Integrated QMS.