Innovation

Expertise and know-how in advanced

wound care gelling fibre technologies

Regulatory

Experienced Regulatory and Quality team

regulatory compliance throughout a product’s life cycle.

Manufacturing

With over 40 years of know-how and

know-why in non-woven gelling fibres

About SFM!

Speciality Fibres and Materials Limited is a specialist gelling fibres and x-ray detectable yarn manufacturer to the advanced wound care sector. For any details about our products and capabilities, please contact our Commercial team.

Our products

Our product portfolio is home to developments such as x-ray detectable yarns, calcium alginate dressings, reinforced calcium alginate dressings, modified cellulose dressings and their antibacterial equivalents.

Available in roll form, cut pieces, packed and sterile. A sustainable fabric, with high absorbency and tensile strength. Available in various sizes and GSM.

Promotes intact removal, one of the strongest reinforced Alginate fabric in our portfolio. 510K cleared. Available in various sizes and GSM.

As part of our Alginates range, SFM offers antibacterial options for both the standard Alginates and reinforced products. Available in various sizes and GSM.

Our carboxymethyl cellulose and cellulose Ethyl Sulfonate products provide high absorbency, superior wet and dry tensile strength, to promote healing in a moist environment. Available in various sizes, sterile and non-sterile, various GSM available. CE marked.

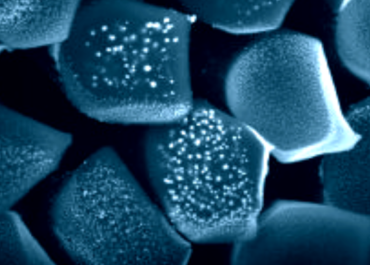

SFM have established proprietary technology in the development of cellulose fibres with silver nanoparticles (AgNP), which are used to form highly absorbent, antibacterial wound dressings. Contact us for more details.

Micropake® is a phthalate free X-ray detectable yarn. Manufactured in a range of linear densities, strengths and colours to suit customer specifications. Soft and flexible in nature, coupled with good tensile strength.

FREQUENTLY ASKED QUESTIONS

SFM has a team of scientists with experience in manufacturing gelling fibres and x-ray detectable filaments. Our customers often come to us with bespoke concepts and we are fully equipped to help them develop their concept, using our scale-up facilities and internal research and testing laboratories. Many of our customers are in the advanced wound care and surgical sector. However we also support customers in other sectors such as food technologies, filtration technologies and the cosmetic industry.

SFM implements and complies with the ISO 13485 (EU, Canada, RoW), 21 CFR 820 (USA) and Ordinance 169 (Japan). We are experts in the overall planning and delivery of regulatory compliance throughout a product’s life cycle. We deliver products CE marked and or FDA cleared. Our Regulatory Affairs and Quality team manage our Integrated QMS.

We keep some stock for the most commonly requested sizes for our x-ray detectable yarns, and therefore can deliver these on-demand. Most of our products are made to order, and whilst we often will work 12 weeks ahead with most of our customers to help manage a smooth continuity of supply which is particularly relevant with the current Covid-19 pandemic; We can often deliver in a few weeks and will try our best to meet your schedule. Packed and sterile products however will be between 8 to 12 weeks once the packaging has been fully approved.

All our products are manufactured in the UK, from class 8 clean room facilities located in Coventry. Our alginates, reinforced alginates, gelling fibre products are all manufactured from raw materials that are sustainable and using a manufacturing process which minimises waste as far as possible.

We can currently provide our products in several sizes from 5cm x 5cm cut pieces to 20cm x 30cm, although we can provide larger sizes on demand. We can provide our alginate and modified cellulose fabric in roll format, slit reels, cut pieces, ropes depending on requirements. These can be provided non-sterile or packed and sterile. Our x-ray detectable filaments can be provided in different coloring, although black and blue are most common, and in various decitex.

Years Experience in fibre manufacturing

Gelling fibre rolls

Invested in new manufacturing facilities